IV

North British Distillery, Edinburgh

January 15th, 1923

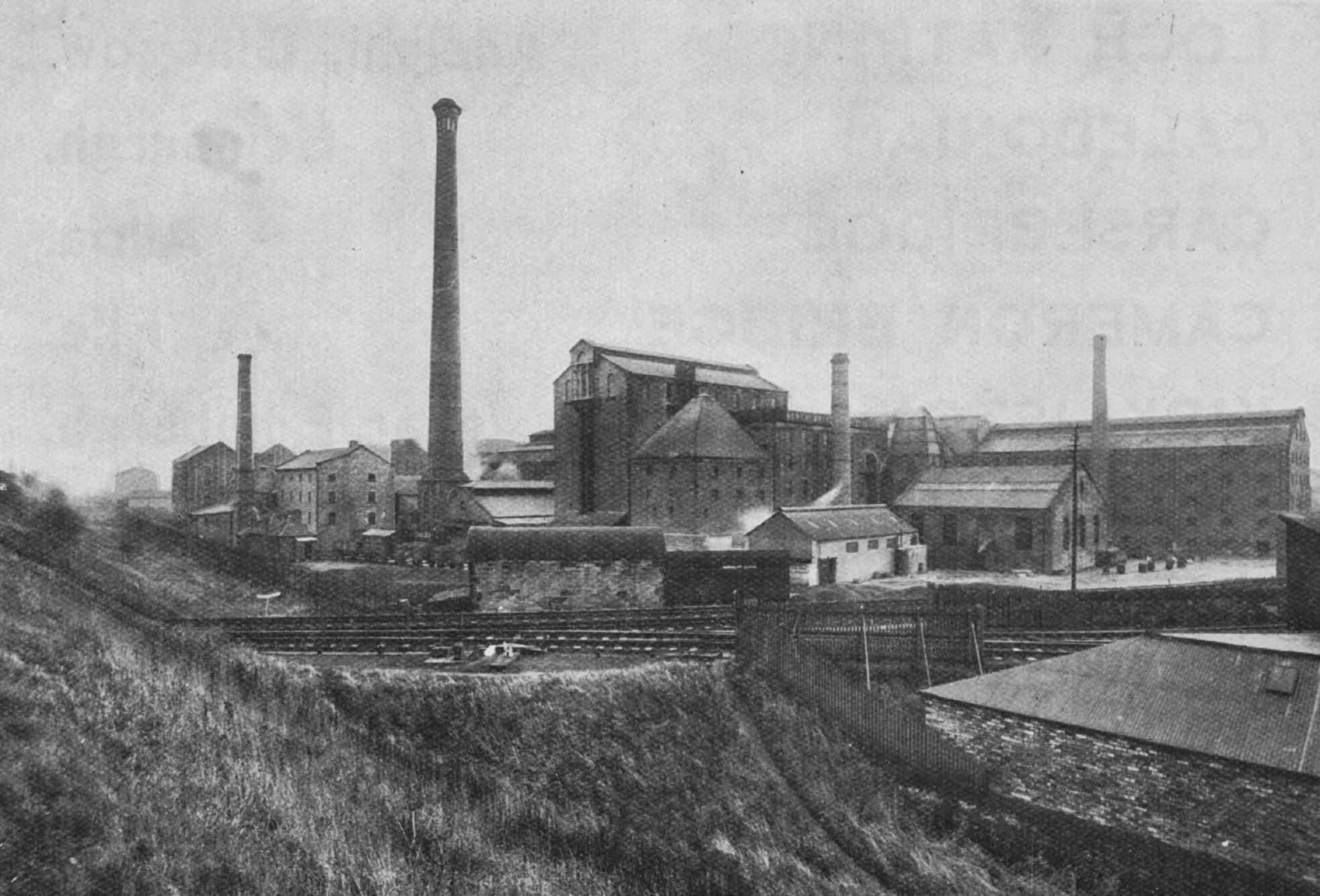

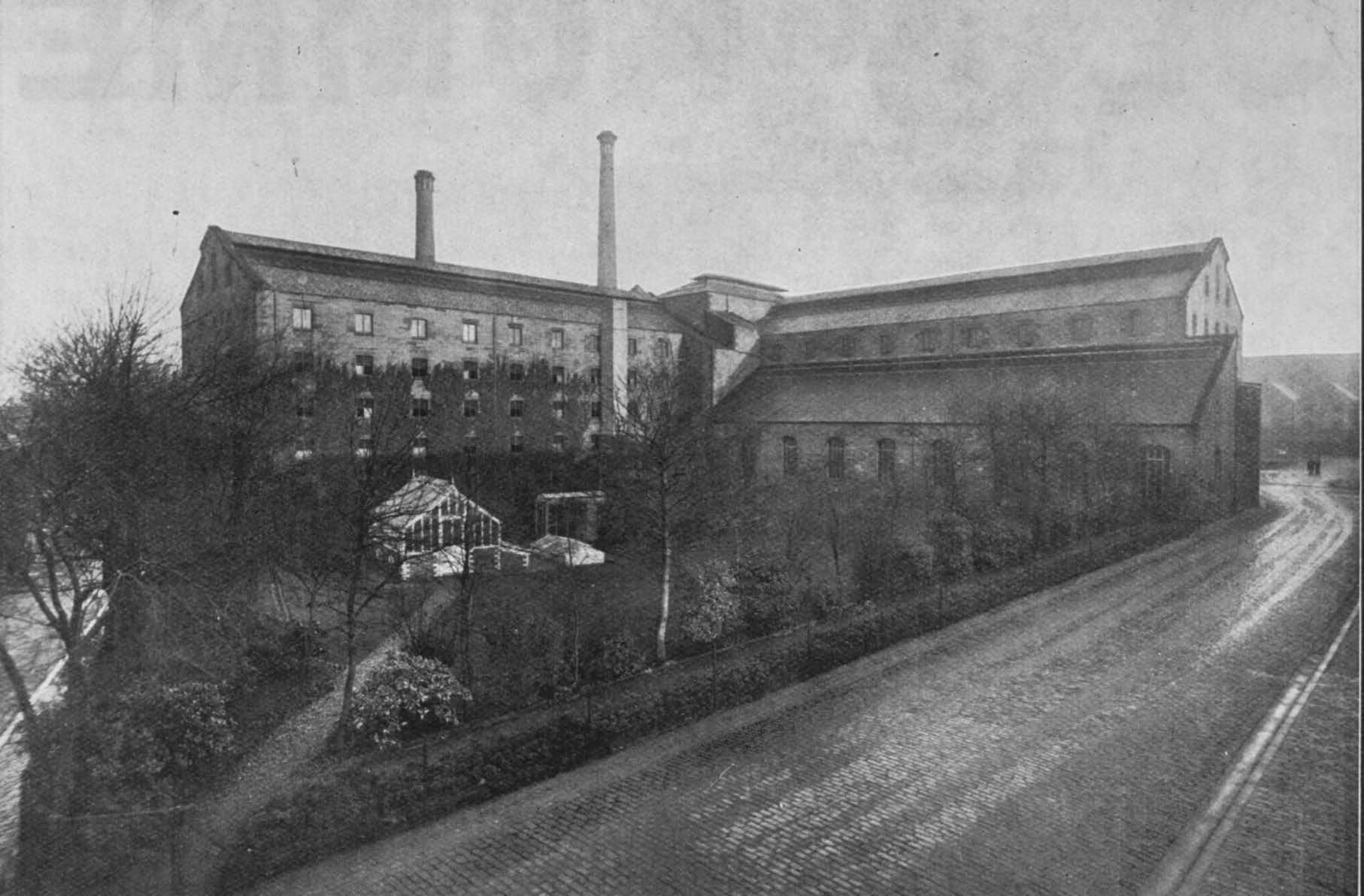

The North British Distillery, which is one of the largest in the world, comprises an imposing group of buildings covering twelve acres of ground two or three miles from the centre of Edinburgh. It was built in the year 1887 by members of the wholesale Whisky trade with the view of conserving the interests of the distributive branch of the industry, and it still occupies a unique position.

The “North British” is well known in Trade circles for the high standard of its produce, which finds a place in all the famous blends.

Near the entrance are the well-appointed offices occupied by the directors, managers and administrative staff. Leaving this building, the visitor is impressed by the five-storeyed maltings, with a square garden of trees and flowers in the foreground, lending an unusually picturesque appearance to this part of the works. The various grains in use, foreign barley, maize, and oats, are run from the main railway line into a siding behind the maltings. From the trucks the grain falls directly into a bin sunk between the rails, and is removed to the five immense granaries at the top of the maltings by a screw conveyor and elevators. Before being steeped, the grain is thoroughly cleaned in two Boby cleaners, and then dropped to the steeps on the floor below. With no fewer than eighteen steeps, each containing from 30 to 50 quarters, the accommodation in this department is exceptionally large. From the steeps the barley passes through chutes directly into the malting drums. These drums, eighteen in number, stand parallel to one another on the ground floor of the maltings, and in the interior of each are revolving cylinders for turning the malt, and perforated tubes for the circulation of air. A temperature of from 60 to 65 degrees is maintained inside the drums, which all have a capacity for 50 quarters, the barley remaining inside them for about nine days before conveyance to the kilns.

The kilns at the North British Distillery are a feature of special interest. Instead of square floors for drying the malt, the kilns take the form of cylindrical drums, heat being supplied by means of perforated tubes running through the centre of the appliances, which convey flue gases, and so provide a well-distributed furnace in each case. There are four kilns of this pattern. Two Bamford mills grind the malt after it has been conveyed from the kilns to the silos, or storage bins, which number 21, each holding quantities of malt up to 100 tons. The grain or malt falls down through a chute into the hopper feeding the mills, whence the grist is conveyed by elevator to a screw, which in turn carries it to an automatic weighing machine, fitted with bags of 2 cwt. capacity.

The turning process, of course, does not apply to the maize, which only requires cleaning, grinding and “cooking” before passing into the mash-tun. Maize-grinding is done by six Bamford mills, and afterwards the maize is fed through hoppers into the cookers. Six cookers, each capable of holding 60 cwts., are employed, and the process, lasting for two hours, is performed by injection of steam at 60 lbs. pressure. Following the cooking operation, the maize is discharged into the mash-tun.

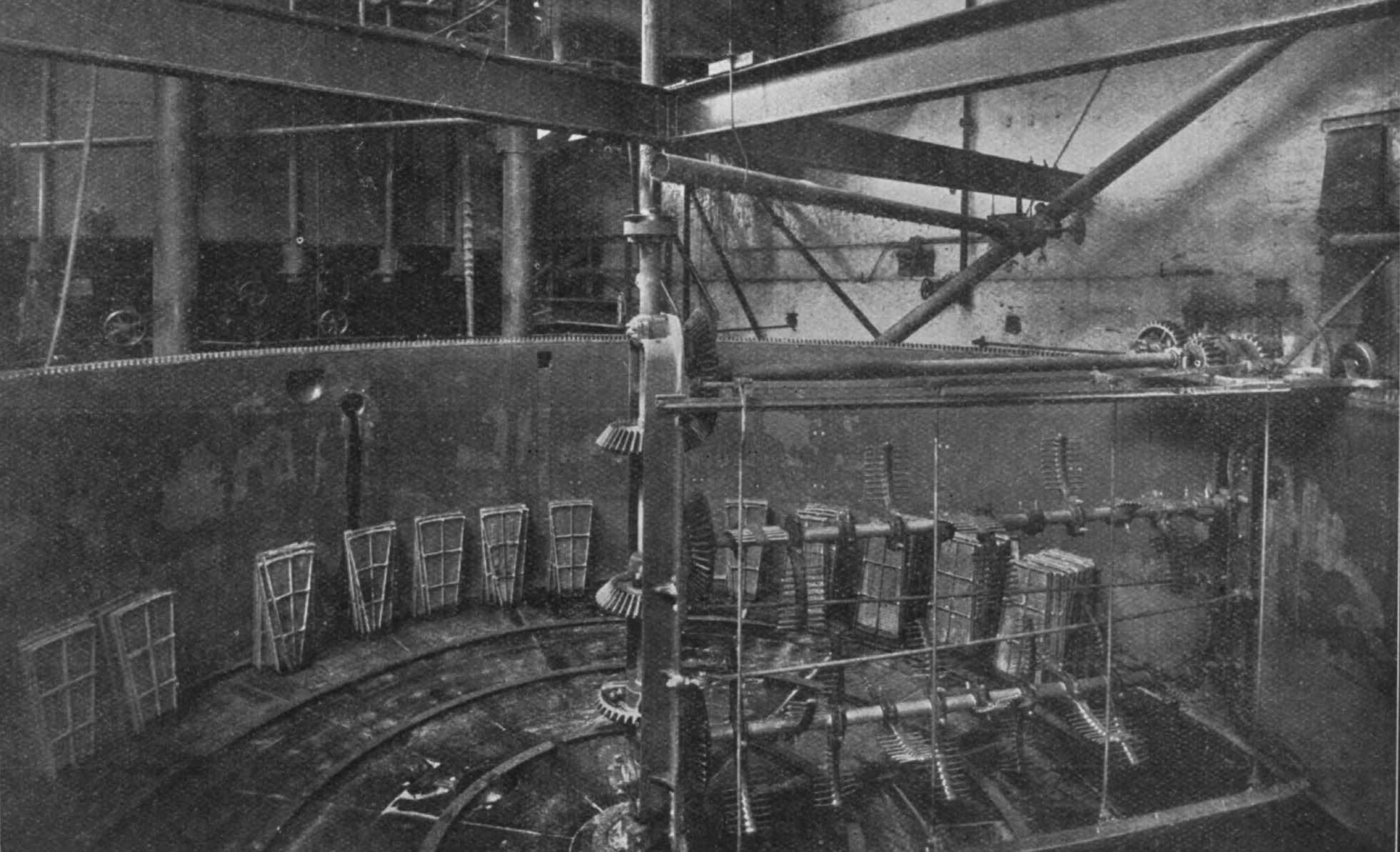

Before the insertion of maize, barley and oats and malts are dropped into the mash-tun, and the whole is stirred by revolving rakes for a period of about two hours, before the wort is drained to the underback. A second water is then added, which also goes to the underback, followed by third and fourth waters used in the next mash. The mashing temperature is 140 degrees, and the composition of the mash is: Maize, 73 per cent. ; malt, 25 per cent. ; oats, 2 per cent. In the mashing process 350 cwts. of maize, 17 quarters of green malt, and 60 quarters of dry malt are used, and these quantities indicate the dimensions of the mash-turn, which is certainly one of the largest, if not the largest, in Scotland.

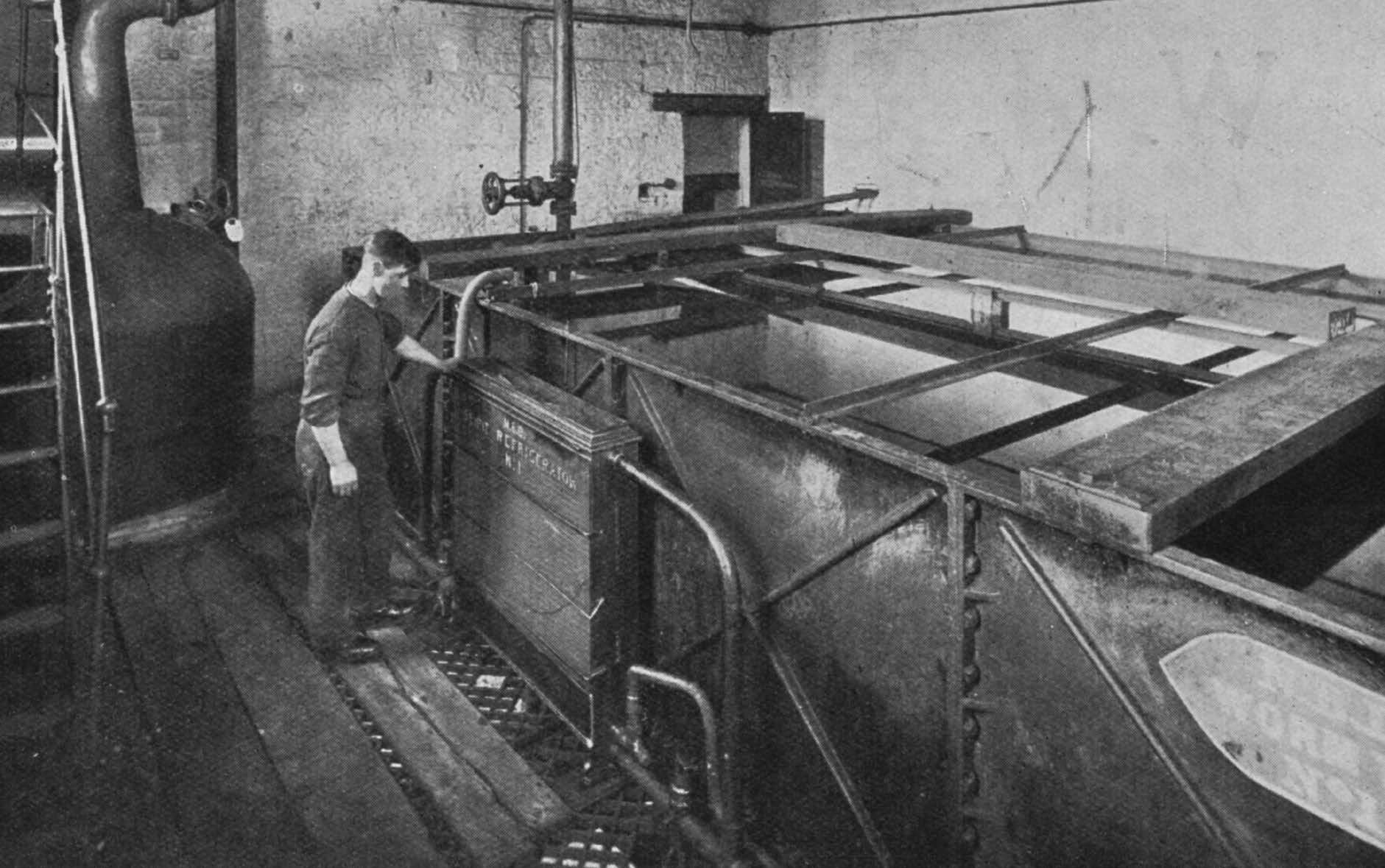

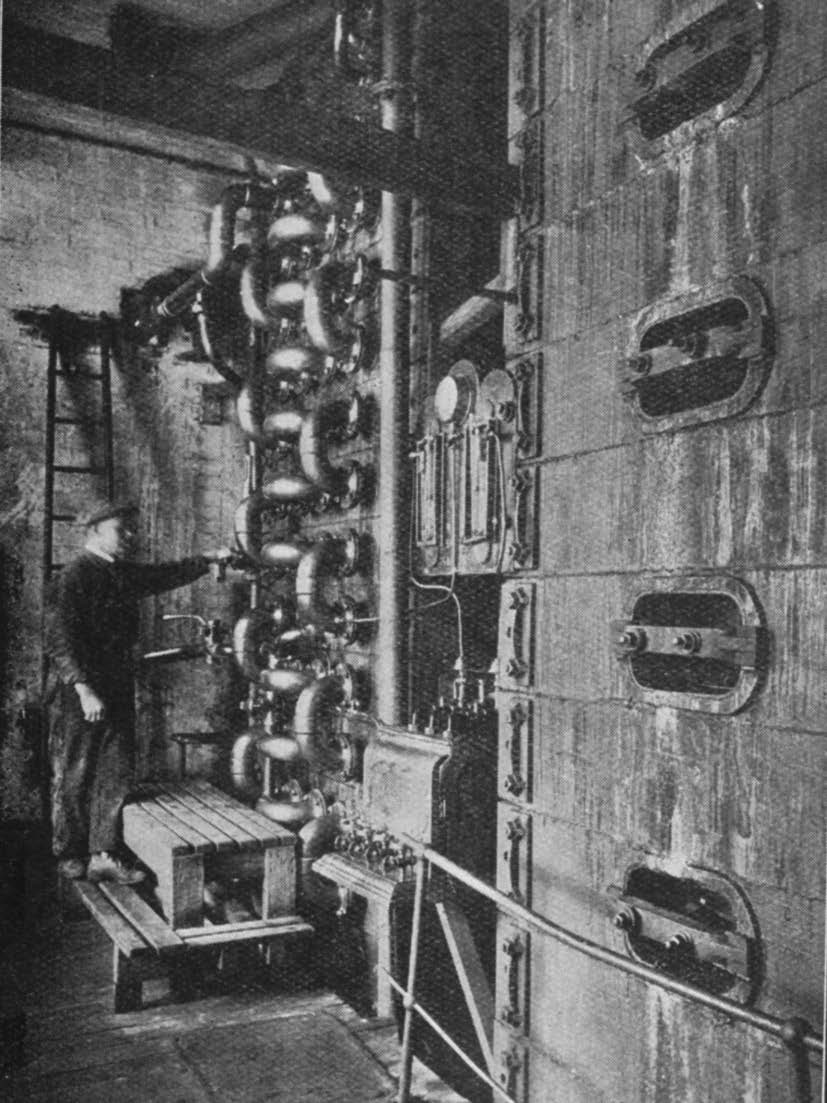

The draff is pumped in the usual manner to a number 2 mash-tun, where it is drained and ultimately dried in three large draff-drying machines, the water in this mash-tun being used later for boiling maize. Passing from the underback to the wort-receiver, and thence to the refrigerator, the wort finally enters the wash-backs, where brewers’ yeast is added for fermentation. The tun-room is an enormous, well-lit apartment, containing no fewer than 20 wash-backs, each capable of holding 40,000 gallons of wash. After fermentation, lasting about 48 hours, the wash, as the liquor is now called, is pumped to the wash-chargers, preparatory to entering the stills. The stills are of the well-known Coffey type, each with rectifying and analyser columns, towering to a height of forty feet. The rectifying column comprises a continuous copper pipe winding throughout the column, as shown in the illustration, and the “analyser” is simply an arrangement of shallow compartments divided by sheets of perforated copper.

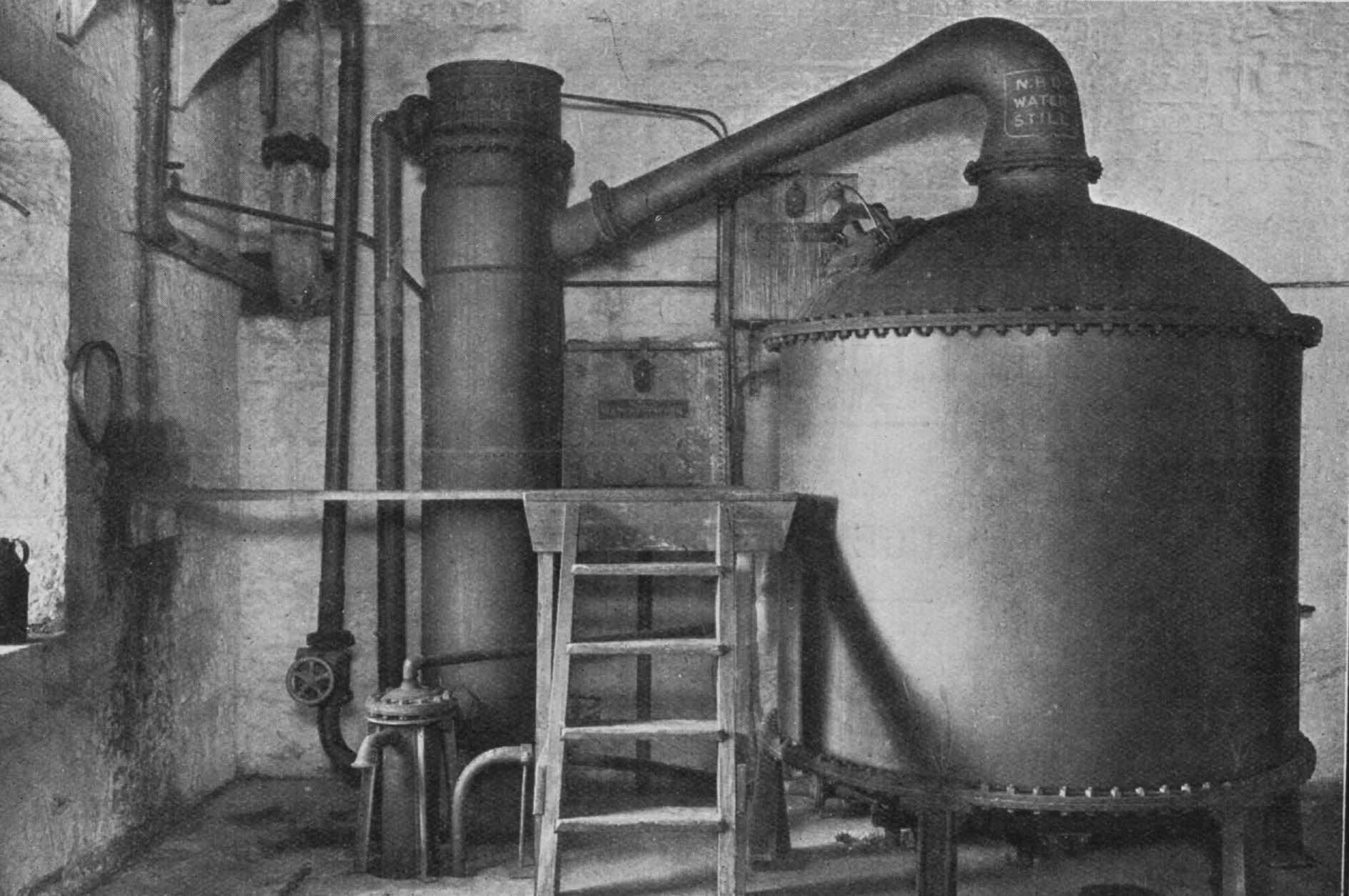

Pumped in at the top of the rectifying column, the wash flows downward through the tubes, and is gradually brought to boiling point by steam from the analyser column which rises through the perforated plates separating each compartment. Reaching the base of the rectifying column, the boiling liquid is then pumped to the top of the adjacent analyser column, where the actual Spirit is separated from it in vapour form by the steam rising up through the perforations in the copper plates. The vapour released from the wash is now carried upwards and back into the rectifying column again, while the spent wash trickles down the analyser column, and ultimately passes to a large dreg-pond to be dried, and later sold as paste. The distilling process is completed when the spirit vapour meets the incoming cold- wash in the rectifying column, and condenses, before being run into a worm-tube placed in a cold-water tank. Through the worm, the Spirit passes on to the two Spirit receivers, each of 7,000 gallons’ capacity, at the rate of roughly 1,000 gallons per hour, where it is examined by the Excise authorities. Finally, the Spirit goes to the Spirit store for reduction, casking, and conveyance to the bonded warehouses. It is interesting to note that all reducing at the North British Distillery is effected by distilled water, and two small pot-stills are maintained for this purpose. Three thousand proof gallons of Whisky are obtained from each wash-back, and, to give an accurate impression of the tremendous dimensions of the warehouses, it is only necessary to mention that the total floorage covers 25 acres, with accommodation for some 75,000 casks.

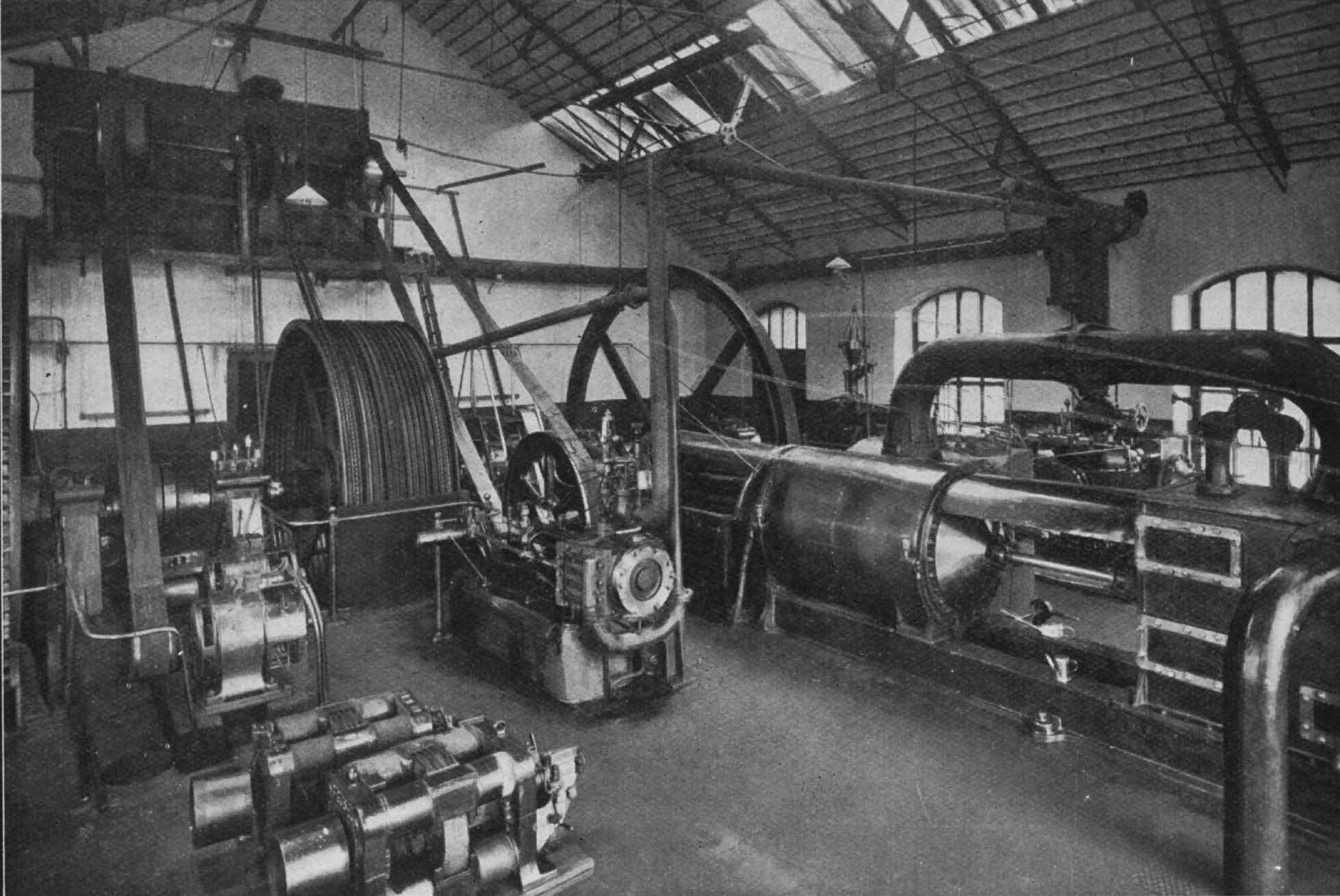

On a gigantic scale also is the power plant. In the central power house are two main engines each of 300 h.p., used alternately for periods of six months. The distillery was one of the first buildings in Edinburgh to be installed with electric lighting, and it is interesting to see a dynamo thirty-six years old, and used until recently, contrasting with the more modern machinery. For heating purposes there are seven steam boilers, as well as nine Lancashire self- feeding boilers for the dreg-plant. There is also a special boiler for driving the maltings during the week-ends, when the main engines are closed down.

It is scarcely necessary, when writing of such an up-to-date distillery, to add that the cooperage and workshops for repairs and other purposes are in the highest state of efficiency, the whole premises being self-contained, and admirably arranged for production of the finest Grain Whisky.

Images © The British Library Board