III

Hazelburn Distillery, Campbeltown

December 14th, 1922

Hazelburn Distillery is one of many in Campbeltown that have recently come under new management, with exceedingly beneficial results. The change of ownership in most cases has taken the local trade out of an old- fashioned rut that was slowly paralysing initiative and diverting the eyes of the distillers from the up- to-date methods that modern science has placed at their disposal, and since its purchase three years ago by Messrs. Mackie and Co., Distillers, Ltd., the makers of the celebrated “White Horse” Whisky, Hazelburn Distillery has undergone changes which may be legitimately described as revolutionary.

Visiting Hazelburn, one is immediately impressed by the well-appointed offices and laboratory, which are in themselves an eloquent sign of the enterprise that is transforming the Campbeltown distilleries, and charging the local industry with new life. The actual process of distilling differs slightly from the method by most of the firms in the town, and owing to scientific control, special treatment of the water supply, and close co-operation between the theoretical and practical staffs, Hazelburn can produce a Whisky which will bear comparison with any made in the district.

The barleys used are principally heavy Scotch and Danish, the latter being said to be as good for malting as the home-grown grain. After cartage from the quay, distant half-a-mile from the distillery, the barley is placed into a hopper for elevation to the four lofts, with a total capacity of 8,000 quarters. Elaborate labour- saving machinery has been installed. Two intake elevators serve a system of conveyors in each of the four lofts, and three turning conveyors automatically turn the grain and load the steeps. There are six large malting floors, and aeration is facilitated by a special air-compressing engine connected with the aerating pipes in the steeps. The entire malting plant is worked by a fine 46 h.p. horizontal engine, which is enclosed by glass partitions for protection against dust.

Three kilns, controlled by King’s patent regulators, and floored with tiles, are conveniently placed for drying large quantities of grain, and the furnaces are heated with peat and coke. The method of storing the fuel is carefully designed to ensure a regular supply for each kiln, the peat and coke being tidily stacked in recesses adjacent to the furnaces. Tiled floors are used in preference to wire, since it is contended that the tiles afford a more even temperature. In the mill room grinding is carried out by a Porteous malt mill, which in one hour deals with twenty quarters of malt, and by its side stands a cleaning and polishing machine.

Entering the distillery building, the visitor sees further evidence of progressive management in a 38 h.p vertical engine for driving the mashing and distilling plant. The temperature of the water in the mash-tun is 148 degrees F., and the worts are cooled to 72 degrees before passing into the eight wash-backs for fermentation. Switchers for breaking the surface “head” in the wash-backs are operated by an 8 h.p. vertical engine. The Spirit store has a vat of 7,000 gallons capacity, and the usual output for the season is 170,000 gallons.

A notable feature at Hazelburn is a large draff-drying machine worked by a third powerful steam engine. Some of the draff is sold wet to the farmers, and a large room with special plant is used for research work in connection with the discovery of the best methods of converting the unwanted grain into cattle food. From the other Campbeltown distilleries, with one exception, the draff is carted to a central storehouse, where it is dried and stored until fetched away by the farmers for feeding purposes. Notable also is the fact that the distillery has private supplies of water and peat – two commodities which largely determine the flavour of the Whisky. The peat is obtained from hundreds of acres of rugged moorland rented by the firm, and efficient transport is provided by a light railway and motor lorries. The premises are lit entirely by electric light.

Hazelburn is exceptionally well served with storage. In addition to six bonded warehouses of 600,000 gallons joint capacity, there is an enormous general warehouse with space for nearly 700,000 gallons of Whisky in cask. To this general warehouse comes Spirit from all parts of the country, and it is interesting to note that a consignment of no less than 124,000 gallons was recently shipped to Campbeltown from Messrs. Mackie’s Craigellachie-Glenlivet distillery in Banffshire. Even the local people, it is said, smacked their lips joyfully when the two heavily-laden ships carrying this immense cargo lumbered into the bay.

Hazelburn maintains a splendid laboratory in charge of a qualified chemist, and the striking results achieved in this department must almost cause many of the past generations of distillers to turn in their graves. The laboratory is not merely used for theoretical research work; it is an integral part of the distillery, and moves hand-in-hand with the practical branch of the business. Its actual function is two-fold. Firstly, control of material and processes is regularly and continuously carried on, analytical details of every substance employed being carefully tabulated, circulated and kept for reference. Thus the use of undesirable material of any kind, from the initial barley to the resultant Spirit, is avoided, and only such materials as have passed severe tests are allowed to go through the hands of the practical man.

Samples of barley, for example, are submitted to the chemist well in advance, and by an ingenious adaptation of a certain instrument, the result of five years of patient research, he can readily discover the exact amount of Spirit that the grain should ultimately yield. At the completion of the first stage of manufacture – the production of the malt for mashing – each sample is analysed, and reports are issued to the operators concerned as a guide to the direction of subsequent processes. When mashing commences the resulting wort is also examined scientifically to ascertain the proportions in which desirable sugars are present.

Next in order, and most important, is the scrutiny of the living yeast before it is used for fermentation. Such analysis is carried out under the microscope to discover the nature and activity of the living cells, the proportion of undesirable bacteria, and the proportion of dead to living cells in the yeast itself. Further, the ability of the yeast to ferment, and the degree of its fermentative power are also determined.

To facilitate these tests the whole process of distilling is carried on in a miniature distillery which has been cleverly fitted up in the laboratory. This is a fascinating little apparatus, including a liliputian malt-mill modelled precisely on the lines of the large machine in the malt-house. Mashing is done in small glass vessels, and the “worts” pass for fermentation into flasks which are placed in an incubator of 86 degrees temperature. A small glass still completes the outfit.

The laboratory is in constant communication with the three other distilleries owned by the firm, and the work done in each is charted to show the percentage of efficiency gained, 97 per cent. being the set standard. Research is the secondary function of the laboratory, and in this direction the skill of Mr. Hastie, B.Sc., the resident chemist, has brought about many improvements in the production of the Whisky.

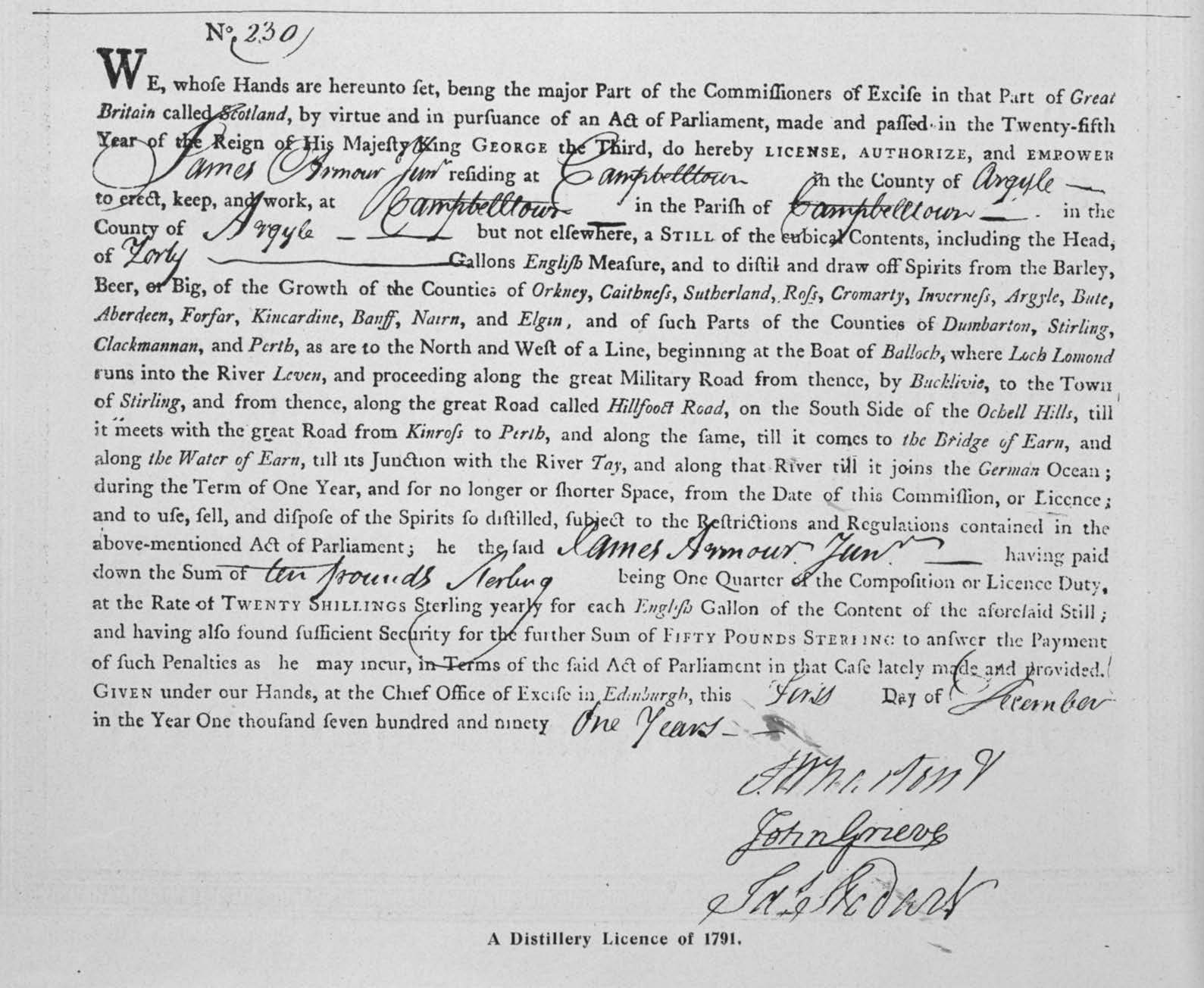

As in the case of the other Campbeltown distilleries, Hazelburn had its origin in one of the smuggling “bothies” for which the geology of Kintyre is naturally adapted. In the year 1725 some thirty-two distilleries were at work in the locality, and records preserved at Hazelburn in the form of a licence dated 1796, and balance- sheets for 1794, prove that the present site is one of the oldest in the town, although the output of the original plant must have been very limited.

For this account of the distillery we owe much to the assistance of Mr. Innes, the manager, who is one of the able men “imported” to Campbeltown from the north-east of Scotland.

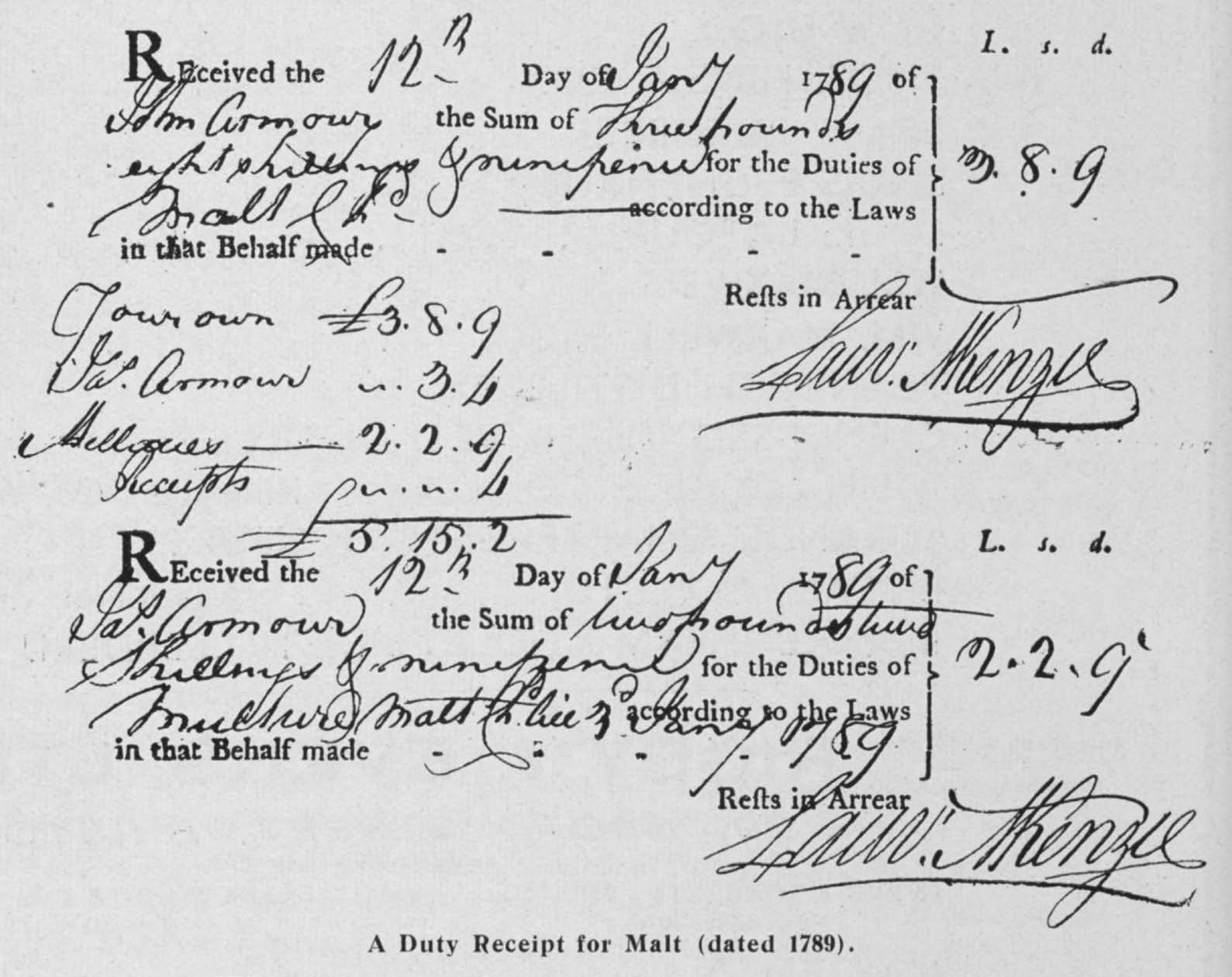

Apropos the above article, we reproduce a distillery license dated 1791 and a duty receipt for malt dated 1789. The original documents are the property of Mr. Archibald Armour, Longrow, Campbeltown.

Images © The British Library Board